Efficiency and productivity are crucial in today’s fast-paced industrial environment to keep a competitive advantage. The process must be not only technical and permanent, but also fast and economical for stainless-steel fabricators and welders. High-performance stainless steel MIG wire UDO ลวดเชื่อมสแตนเลส YAWATA 308L-16 helps make this possible. In this article, we will take a look at how switching to premium stainless steel MIG wire can improve weld speed and productivity by x% and thus enhancing overall operational efficiency. So if you want the best all-around stainless Welding Wire and you are serious to make the investment in to a little high quality products like Yawata-308L-16.

Welding Speed and Productivity: Why It Matters?

Welding speed and productivity are vital metrics in any fabrication shop, manufacturing facility, or job site. Quicker welding results in shorter cycle times, decreased labor costs and higher throughput. But these advantages come with a caveat, as the quality of the welds must be compromised to ensure structural integrity and prolong their service life. Stainless steel is a versatile material that is commonly used in both household and industrial applications where its corrosion resistance, aesthetic appearance, and performance qualities are important. The most important thing to achieve these goals is using a high-quality MIG wire specifically designed for stainless steel.

Significant Advantages of High-Quality Stainless Steel MIG Wire

Consistent Arc Stability

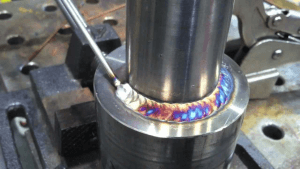

A stable, consistent arc is one of the main reasons for faster welds. Premium quality stainless steel MIG wire is designed by incorporating an effective chemical composition which maintains an even arc under all welding conditions. This consistency also limits downtime and minimizes the adjustment time, allowing welders to operate in a continuously-flowing manner. Stable arc also helps in achieving uniform weld beads, thus minimizing the chances of defects that need rework.

High Deposition Efficiency

Currently, only older Generation 1 machinery is able to deposit weld metal per pass, helping to save internal costs, better utilizing welding materials. In high-volume production scenarios where time and material costs matter a great deal, this feature is crucial. High quality MIG wire (stainless steel) such as Yawata-308L-16 produces an impressively high deposition rate. Not only is this more efficient by welding more of a contact surface together, but it also shortens production cycles, and therefore project time, with substantial cost savings.

Less Mess and Cleanup Time

One of the most common challenges when welding is excessive spatter, resulting in added cleanup and finishing work. MIG with high-quality stainless steel minimizes spatter due to its refined formulation, and stable arc characteristics. With reduced spatter, we not only have a significant increase of the weld quality, but also less time required for cleaning afterwards. This efficiency allows frets to focus on production rather than remediation, improving overall productivity.

Enhanced Heat Control

Stainless steel needs to be maintained at a specific level of heat without becoming compromised by burn-through or distortion, which slows production and creates a lot of waste. Next is the premium stainless steel MIG wire which aims at delivering exceptional heat control, specifically ensuring that the required amount of heat applied to the workpiece. By controlling the heat input during welding, the weld maintains its integrity, and overheating is prevented with defects, resulting in expensive repairs, significantly reduced.

User-Friendly Operation

Another important factor that makes welding quicker is what is called ease of use. Inherent ease of use, in turn, allows less experienced welders to make predictable, high-quality welds without lengthy training or frequent adjustments of the welding process. High-grade, stainless steel MIG wire, such as the Yawata-308L-16, undergoes a variety of things that all conspire to provide a greater degree of consistency in the weld; from the manufacturing process to the intended use they work to help cover that learning curve while achieving quicker processes.

How Faster Welding Leads to Increased Productivity

The net effect of these technical advantages is a big boost to productivity. That’s how high-quality stainless steel MIG wire aids in faster, more cost-efficient welding processes:

Less Downtime: Improved arc stability and low spatter results in fewer stops for adjustments and cleaning keeping production running.

Decrease Material Waste: High deposition efficiency reduces the quantity of filler material per weld, lowering overall production costs.

Reduced Downtime: Optimized welding settings minimize equipment downtime and setup time, allowing for more consistent production and savings.

Improved Quality: Excellent welds create less rework, ensuring projects are up to par when completed.

Reduction in costs: The optimization of the welding process procures a major decrease in the costs, including labor, materials, and service costs.

When every second matters in the production process, these optimizations can translate into meaningful competitive benefits, positioning premium stainless Welding Wire as a valuable investment in any workshop or manufacturing facility.

Track Wire and Track Marker, YAWATA-308L-16; A Best Seller for High Speed, High Quality Welding

The Yawata-308L-16 is one exceptional product in the world of stainless-steel MIG wire. Top of the line, this stainless steel welding wire provides high efficiency for the most demanding of applications. With its advanced formulation that provides a stable arc, high deposition efficiency, and low spatter, it is your reliable and economical solution for virtually any project.

The Yawata-308L-16 is an ideal answer for such users who want to increase the welding rate Only the competition with out0534161 quality. The reason we are chosen as the stainless Welding Wire professionals; it is proven getting high demand applications.

Conclusion

Efficiency is the name of the game in modern manufacturing. If you’re looking for a way to enhance welding speed and productivity, not to mention achieving flawless, trouble-free welds that are durable throughout a workpiece’s lifespan, the addition of quality MIG wire can do wonders. The advantages of using premium stainless Welding Wire UDO ลวดเชื่อมสแตนเลส YAWATA 308L-16 consisting of a stable consistent arc, high deposition efficiency, lower spatter, and excellent heat control are obvious. Not only does this translate to faster turnaround times and cost savings, but it also means that your welds will meet the highest possible quality.

If you are prepared to maximize your output and secure better welding, checking out products such as Yawata-308L-16 is a great investment. Find out how the right kind of stainless Welding Wire could change the game for your welding Businesses, check us out at UDO Thailand today and redefine your welding work.